The closure of the UNEXMIN H2020 project

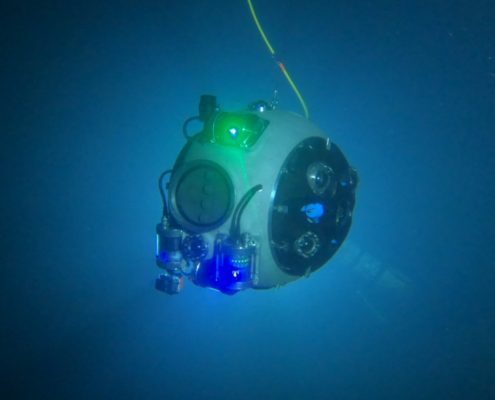

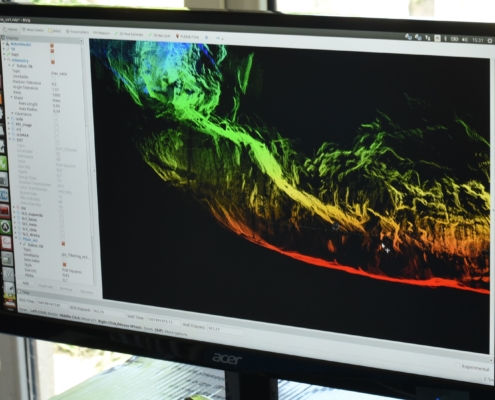

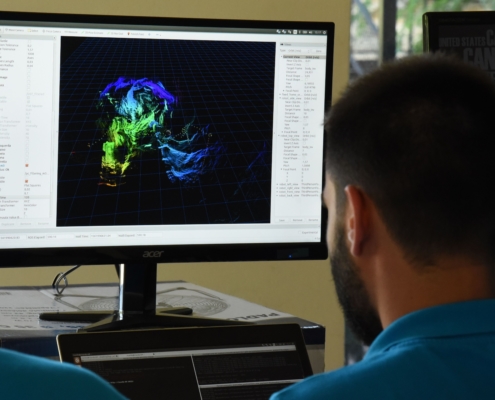

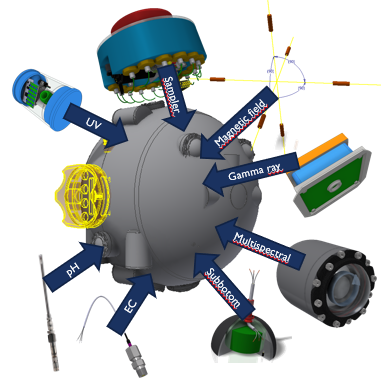

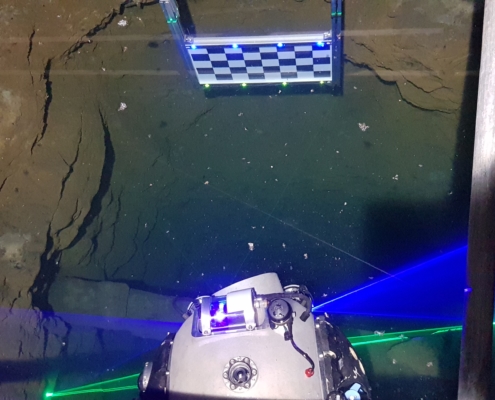

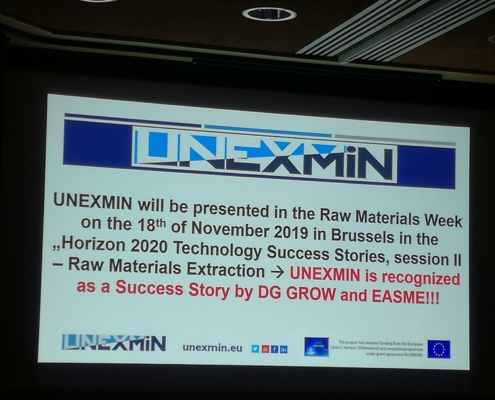

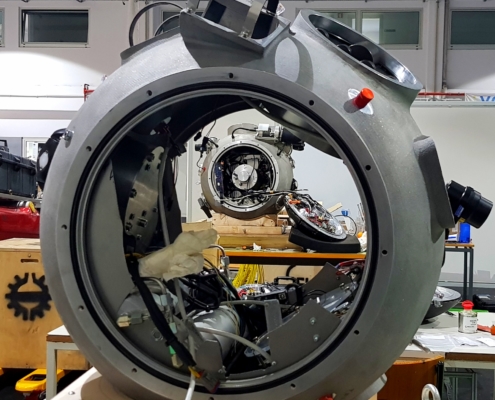

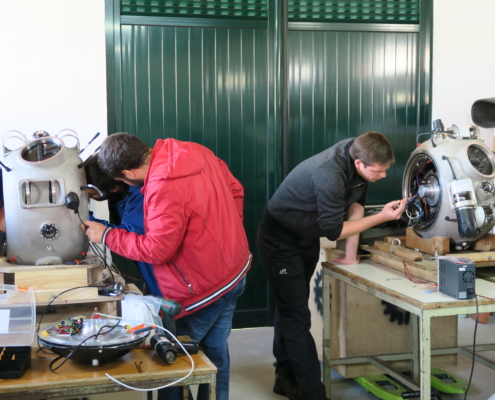

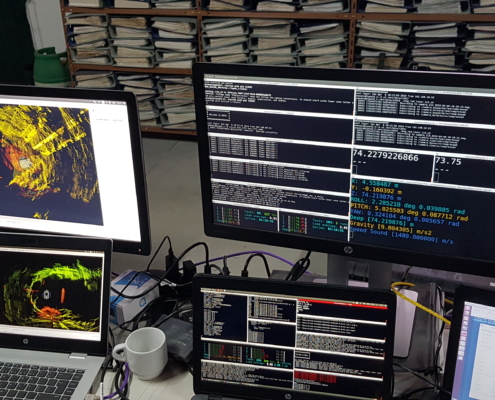

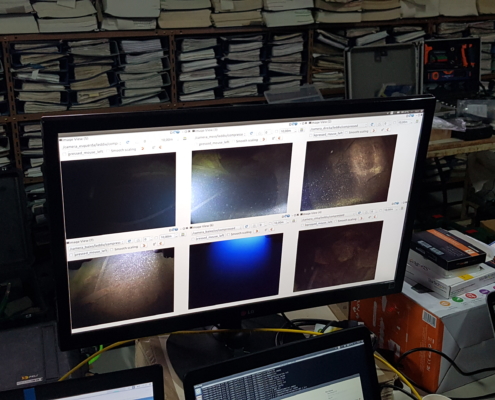

UNEXMIN – Underwater Explorer for Flooded Mines – started in February 2016 and, after almost 4 years of progress, ends this October 31st. In the end the project has achieved what it promissed, supported by a multi-disciplinary team of European partners. The outcomes include, among others, the UX-1 prototypes, a new technology line made available to explorer flooded mines in a secure, cost efficient way and a robust and unique Inventory of Flooded Mines in Europe.

However, and despite the official closure of the UNEXMIN project naming, the team will continue to develop and perfect the technology to the needs of the market and customers. For this, a brand new project, that will bring the UX-1 technology line closer to the market is on the pipeline. Also, a joint company, supported by UNEXMIN’s partners will exploit the technology – and it is available for work!

Find below some of the most important achievements of the UNEXMIN project, if you want an overview of what the team has done and reached over the past 45 months.

- UNEXMIN kick-off meeting

- UNEXMIN at Tampere Workshop

- Porto follow-up Workshop

- Madrid follow-up Workshop II

- Technology Appraisal Workshop

- Progress Workshop in Porto

- UNEXMIN workshop at La Palma, Spain

- The “Use of robotics and automation for mineral prospecting and extraction” conference was a success!

- First UNEXMIN consortium meeting in 2018. Bled, Slovenia

- First UX-1 prototype assembly is on the way!

- The European Inventory of Flooded Mines is now online!

- Summary of the first week of the Kaatiala trials

- Summary of the second week of the Kaatiala trials

- Summary of the first week in Idrija mine

- Summary of the second week in Idrija mine

- UNEXMIN meeting in La Palma: UX-1 and field trials in the agenda

- The UNEXMIN project was present at the EU Industry Days 2019!

- First week of field work at the Urgeiriça mine, Portugal

- Second week of field work and major achievements at the Urgeiriça mine, Portugal

- Summary of the first week of field work at the Ecton mine, UK

- Summary of the second week of field work at the Ecton mine, UK

- Summary of the third (and last) week of field work at the Ecton mine, UK

- UNEXMIN consortium meeting in Budapest: final decisions and preparations made ahed of Molnár János field trials

- Summary of the field tests at the Molnár János cave, Hungary

- UNEXMIN Final Project Meeting held in Brussels, 25th September 2019

- Outcomes of the UNEXMIN Final Conference

Please continue to follow the UNEXMIN website for further news, as well as the social media channels. They will be kept alive with information whenever possible: Twitter, LinkedIn, Facebook and YouTube.

Last but not least, the UNEXMIN team would like thank all of those who followed the project, who supported the development of the technology and who contributed to make UNEXMIN a reality and a success story in the European Raw Materials panorama.

For any inquiry, about the project and/or any business opportunity, please do not hesitate to contact the project team through the Contact form.

Edit Babinszki

Edit Babinszki