The UNEXMIN final conference will be held in Brussels, on the 26th of September. Registration is open and can be accessed now. It is free!

Dear Sir/Madam,

As the coordinator of the UNEXMIN project, it is my pleasure to invite you to our final conference. This event will be the end of a 4-year journey that led to the development of a robotic platform allowing to explore flooded mines and other flooded structures and environments. During our final conference, you will have the chance to learn more about the project outcomes and its connection to European policies. Come, meet the team and learn all about UNEXMIN!

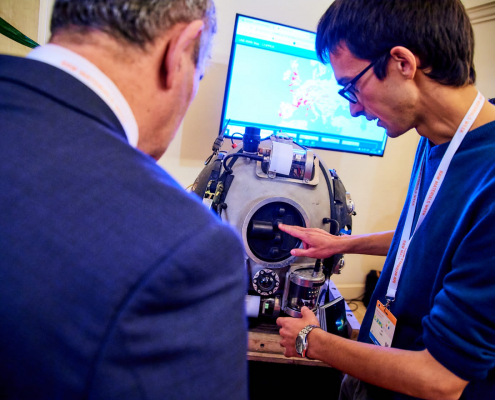

By the way, we will have a very special guest: the first UX-1 robot itself!

See you hopefully soon in Brussels,

Norbert Zajzon

About the event

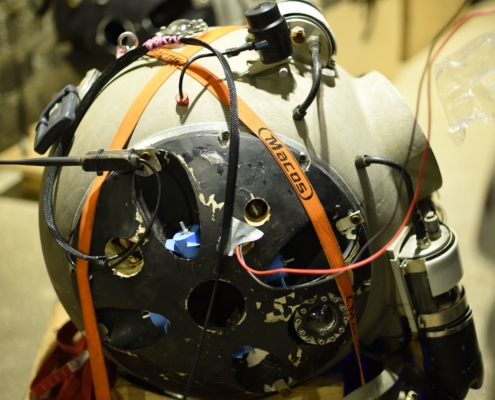

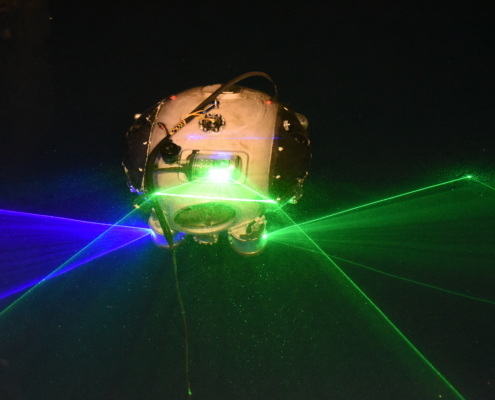

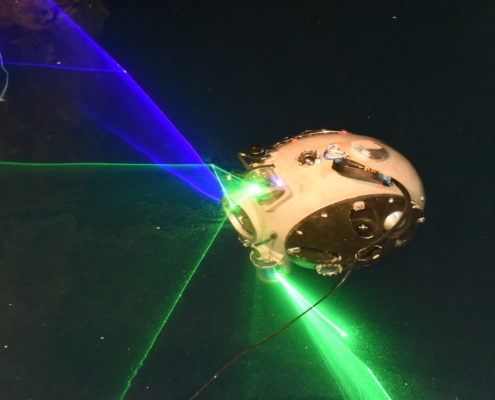

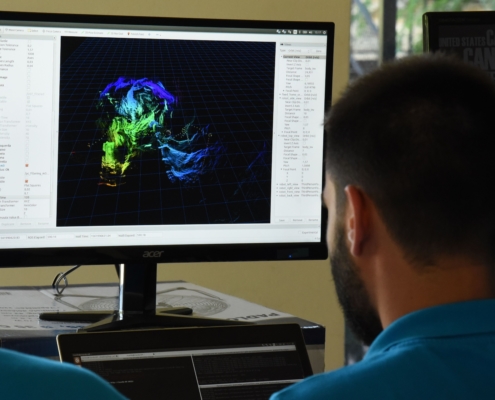

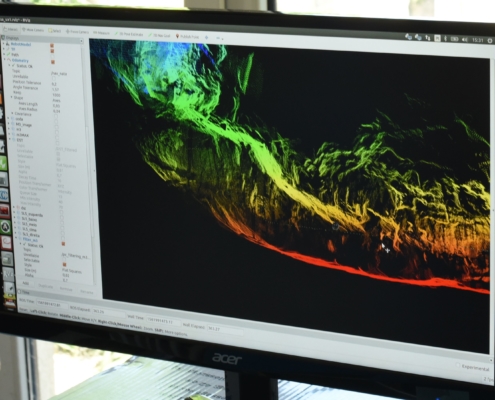

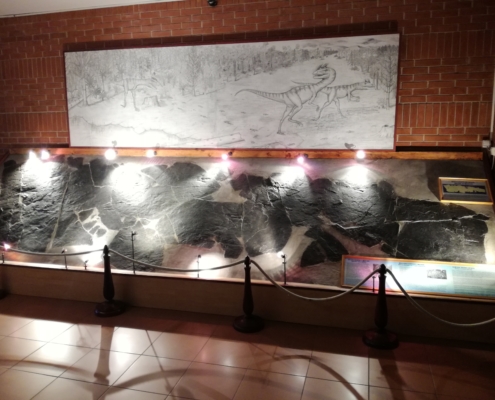

The EU-funded UNEXMIN project is developing a technology capable of autonomous exploration and mapping of flooded underground mines. The robotic platform uses non-contact methods to gather geological, mineralogical and spatial data without major costs or risks associated. The field trials, set up at four different flooded underground mines in Europe, have helped the team to access the platform’s development and to improve this unique exploration technology.

The event programme will include high-level discussions on European innovative raw materials policies, UNEXMIN’s support to those policies, and on the capabilities and future application of the exploration system. The conference will thus provide a unique opportunity to discover the outcomes of the UNEXMIN project and its specific fields of work, including minerals exploration, raw materials exploitation, and robotics and ICT development, with cross-cutting discussions that will demonstrate the impact that UNEXMIN can have on the European landscape. The conference is particularly relevant for EU policymakers, academics, mineral exploration and exploitation companies, cave exploration companies, SMEs focussing on geological consultancy and minerals surveying, and robotics and ICT experts from private and public institutions.

Programme

Several speakers have already confirmed their attendance and you can discover here an overview of the programme:

Morning session: setting the political context: the future of mining in Europe

- Aim of the call for proposals – Marcin Sadowski (EASME, Head of sector – Raw Materials)

- UNEXMIN – aim and outcomes – Norbert Zajzon (UNEXMIN, project coordinator, University of Miskolc)

- ROBOMINERS H2020 project – Claudio Rossi (ROBOMINERS, project coordinator, Universidad Politécnica de Madrid)

Afternoon session I: Raw materials & mining

- UNEXMIN processing and data analysis – Stephen Henley (RCI/4dcoders)

- UNEXMIN field trials and geological interpretation – Gorazd Zibret (Geological Survey of Slovenia)

- UNEXMIN Inventory of flooded mines – Yves Vanbrabant (Royal Belgian Institute of Natural Sciences, EFG-Linked Third Party)

Afternoon session II: Robotics & functionalities

- UX-1 robotic functions: testing and validation – Jussi Aaltonen (University of Tampere)

- UX-1 multi robot platform – Alfredo Martins (Instituto de Engenharia de Sistemas e Computadores, Tecnologia e Ciência)

- UX-1 autonomy, mine exploration and mapping – Claudio Rossi (Universidad Politécnica de Madrid)

Round table – Mineral exploration, future and long-term initiatives

Venue

Royal Belgian Institute of Natural Sciences

Vautierstreet, 29 I 1000 Brussels I Belgium

Registration

Full information is available at https://www.unexmin.eu/unexmin-final-conference

Participation in this event is free but requires registration.

To register, please fill in the form at https://forms.gle/V64vHekSZVbTZmo59

Edit Babinszki

Edit Babinszki