Porto follow-up Workshop

UNEXMIN partners met in the beautiful city of Porto during the 28th and 29th of July.

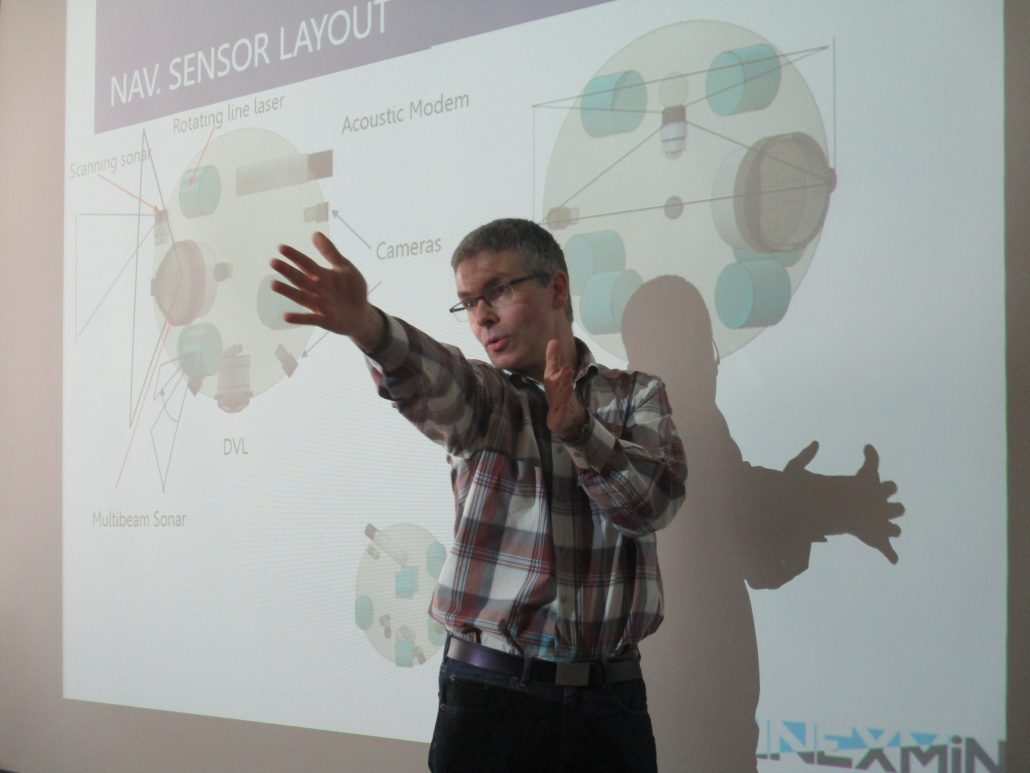

The reason for this reunion was a UNEXMIN follow-up meeting on the project where every currently running Work Package (a block of the work breakdown structure) coordinator presented a review of the work done until now, and a planning of respective future developments.

There were also many relevant discussions on topics related to UNEXMIN’s overall advancement, such as project organisation and the development of UX-1, the multi-robotic platform.

The UNEXMIN team discussing UX-1 developments

One of the main points from this meeting was the debate concerning the first prototype’s construction and development. The questions raised about the project’s progress will have a final and determinant answer when UNEXMIN partners meet in Tampere in September, where they will take part in a one-week-work agenda totally devoted to clarify the next steps to take regarding UX-1.

TURTLE – a robotic autonomous deep sea lander – made from other INESCTEC european project

UNEXMIN partners also visited the labs of INESCTEC (Instituto de Engenharia de Sistemas e Computadores, Tecnologia e Ciência), one of the partners from the UNEXMIN project consortium, who are specialists in sea robotics, and who have past experience in this field related to UNEXMIN. In the labs the consortium could see and learn how the past and current experience in deep sea robotics from INESCTEC will positively impact the UNEXMIN project and the development of a new technology trend – to have a multi-robotic platform capable of mapping flooded mines that are currently inaccessible.

UNEXMIN team at Porto Follow-up meeting