Progress Workshop in Porto

From the 4th of July to the 6th of July, UNEXMIN partners got together for a three-day meeting entitled “Progress Workshop”. As the name indicates, this workshop was a way to control the work being done by every partner in each of the eight work packages, to guarantee that the project is developing in the right way. The meeting was hosted in Porto by INESC TEC at their facilities, which include a robotics development lab.

On the first day of the meeting, there was an overview of the project and a review of the work in each work package. Items included hardware and software developments, preparation for testing the robotic system and communication and dissemination activities. In a multi-disciplinary project like UNEXMIN (robotics, geology, technology development), it is crucial that the different teams share their work with the others. The Advisory Board members – experts in mining and geology – were present during the review of the project and gave their most valuable help to the project partners. Their guidance is very welcome – after all, they have the expertise.

Discussions held during the Progress Workshop

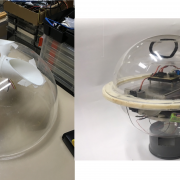

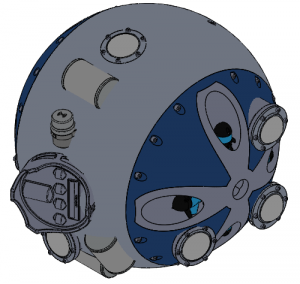

The second day was dedicated to a review meeting of the Work Packages with an evaluator of the European Commission. The evaluator considered the project as running well with everything having been done on time and with good development prospects. After the review, the partners visited INESC TEC robotics labs, where they have a local pool which is used for testing. UPM, who built a UX-1 prototype, tested the robot in the pool, as you can see in the following video.

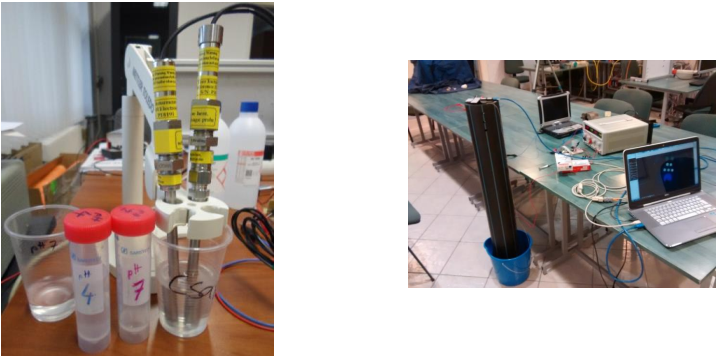

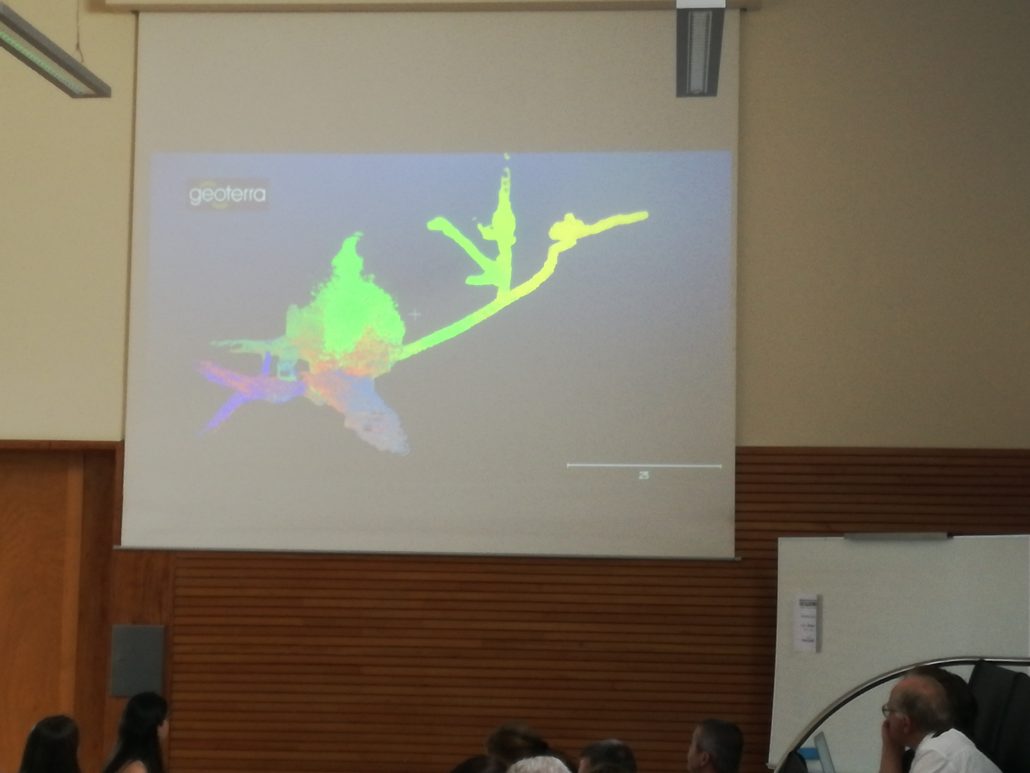

On Thursday, the core discussions for the development of the multi-robotic system were held. These included discussion on Work Package 3 – Autonomy for mine exploration and mapping, Work Package 4 – Multi-robot platform development, and Work Package 6 – Post-processing and data analysis functions. These work packages started recently, so discussions on their structure and content are of high importance.

Post-processing discussion on laser scanner data

There is no time to make mistakes and the consortium is doing their best for the development of the multi-robotic system!